Insulation is more than just a comfort upgrade—it’s a long-term investment in energy efficiency, building durability, and environmental performance. Among the most overlooked yet critical areas of insulation are continuous exterior insulation and below grade insulation, which together address two of the largest sources of energy loss: building envelopes and foundations. Without proper solutions, heat escapes through thermal bridges, moisture seeps into basements, and buildings face higher utility bills year after year.

This is where Expanded Polystyrene (EPS) comes into play. Known for its versatility, durability, and affordability, EPS has become a go-to material for continuous and below grade insulation. In this guide, we’ll explore exactly why EPS is effective, how to apply it in DIY and professional projects, and what benefits homeowners and contractors can expect.

Why Continuous and Below Grade Insulation Matters

Energy Loss Prevention in Foundations and Walls

Energy escapes through any gap or weak point in insulation coverage. Continuous insulation, applied across the building envelope, eliminates thermal bridges where structural elements like studs or floor slabs interrupt insulation. Below grade insulation, applied to foundations and basement walls, prevents energy loss where soil temperature can dramatically affect indoor comfort. Together, these methods reduce HVAC loads, keeping buildings warmer in winter and cooler in summer.

Moisture Control and Long-Term Structural Health

Basements and foundations face constant pressure from groundwater and soil moisture. Without proper below grade insulation, water infiltration can lead to mold growth, material degradation, and structural issues. EPS, thanks to its closed-cell structure, resists water absorption and maintains thermal performance even in damp environments. This makes it especially valuable in areas with freeze-thaw cycles.

Common Problems Without Proper Below Grade Insulation

Skipping below grade insulation leads to multiple issues: condensation inside basements, increased energy bills, and uncomfortable interior climates. Foundations are also more vulnerable to cracking when temperature differences between soil and concrete cause stress. Over time, these small failures multiply into costly repairs.

Expanded Polystyrene (EPS) in Continuous Insulation

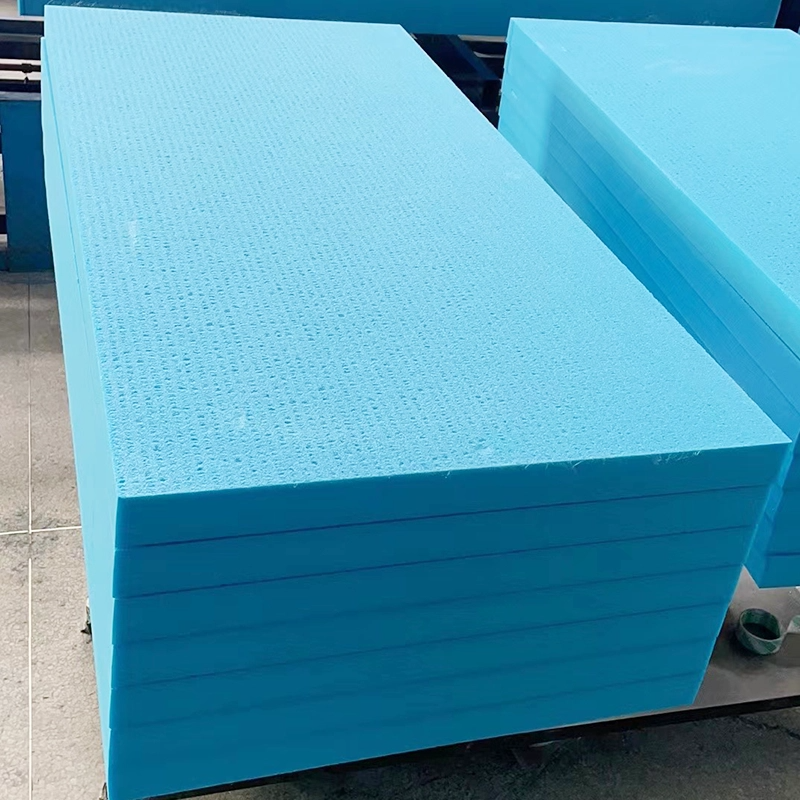

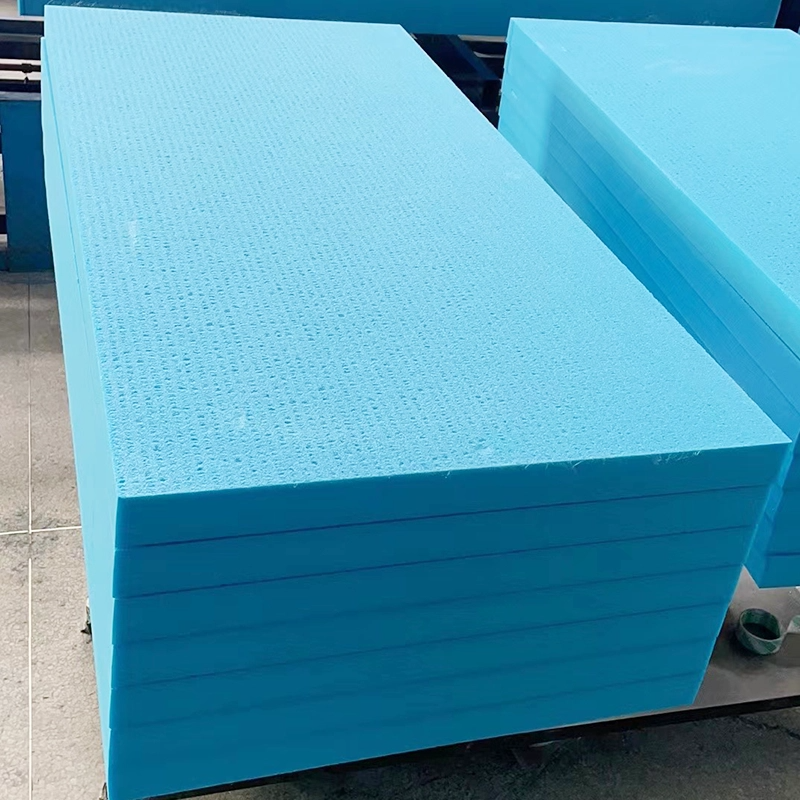

Core Properties of EPS That Make It Ideal

EPS is lightweight yet strong, with excellent thermal resistance. It has a stable R-value that doesn’t degrade significantly over time, unlike some insulation foams that lose blowing agents. EPS can also be manufactured in varying densities, making it suitable for both wall applications and load-bearing foundation insulation.

Comparing EPS with XPS, Polyiso, and Mineral Wool

| Insulation Type | R-Value per Inch | Moisture Resistance | Cost Efficiency | Environmental Impact |

| EPS | 3.6 – 4.2 | High | Very High | Recyclable |

| XPS | 4.5 – 5.0 | Very High | Medium | Higher embodied carbon |

| Polyiso | 5.6 – 6.5 | Moderate | Medium-High | Foil facings improve performance |

| Mineral Wool | 3.0 – 3.3 | Low | Medium | Fire resistant, recyclable |

This comparison shows that while EPS may not offer the highest R-value per inch, its balance of cost, durability, and moisture resistance makes it highly effective for below grade and continuous applications.

Longevity and Environmental Impact of EPS

EPS can last decades underground without significant loss of performance. It does not degrade chemically in soil, and when removed, it can be recycled into new insulation boards or other plastic products. This longevity not only reduces replacement costs but also lowers the building’s overall carbon footprint.

DIY Insulation: 5 Expert Tips on EPS Application

Surface Preparation and Moisture Barriers

Before installing EPS panels, ensure the foundation surface is clean, dry, and free of debris. Applying a moisture barrier or waterproof membrane behind EPS improves long-term performance by keeping groundwater away. Neglecting this step can compromise insulation efficiency and accelerate foundation wear.

Cutting, Shaping, and Installing EPS Panels

EPS is easy to cut with a utility knife or hot-wire cutter. Panels should be dry-fit before final placement to ensure full coverage. Adhesive or mechanical fasteners can be used depending on the surface. Precision is critical—gaps create thermal bridges that weaken the effectiveness of continuous insulation.

Sealing Gaps and Preventing Thermal Bridging

Use spray foam or compatible sealant to close gaps between EPS panels. Even small air gaps can allow energy loss. For above-grade transitions, continuous insulation should wrap around to ensure there are no cold spots at the junction of foundation and walls.

Safety Precautions and Tool Selection

Always wear protective eyewear and gloves when cutting EPS. Although EPS is non-toxic, small particles can irritate skin or eyes. A respirator is recommended when cutting large volumes indoors to avoid inhaling dust. Simple tools like straight edges and foam-specific adhesives improve installation quality.

Maintenance Checks After Installation

After installation, inspect exposed areas regularly for damage or displacement. Check basement interiors for signs of condensation, which could indicate improper sealing. Routine inspections help preserve insulation effectiveness for decades.

Key Performance Benefits of EPS Below Grade

Compressive Strength to Withstand Soil Pressure

EPS is manufactured in densities strong enough to handle significant soil loads without deforming. This is crucial for foundations and retaining walls, where long-term soil pressure can compromise weaker materials.

Resistance to Moisture and Freeze-Thaw Cycles

Unlike organic materials, EPS does not rot or absorb large amounts of water. In freeze-thaw environments, it maintains stability, preventing cracks and insulation breakdown. This resilience ensures consistent R-values over time.

Cost-Efficiency Compared to Alternative Materials

EPS is among the most affordable rigid insulation boards on the market. When combined with its durability and recyclability, the total lifecycle cost of EPS is often lower than that of more expensive options.

Common Challenges with EPS Insulation and How to Overcome Them

Addressing Water Drainage and Vapor Barriers

While EPS resists moisture, it works best when paired with proper drainage systems. Installing perimeter drains and vapor barriers ensures groundwater pressure doesn’t compromise insulation.

Preventing Pests and Physical Damage

EPS can be vulnerable to pest tunneling if left unprotected. Applying a protective coating or mesh prevents rodents or insects from damaging the insulation.

Ensuring Proper Adhesion and Mechanical Fastening

In damp environments, adhesives alone may fail. Using a combination of mechanical fasteners and adhesives guarantees stability, even under heavy soil pressure.

Real-World Applications of EPS in Continuous Insulation

Residential Foundations and Basements

EPS provides consistent thermal protection for basement walls, ensuring lower heating bills and improved comfort. It’s particularly effective for retrofitting older homes with inadequate foundation insulation.

Commercial Building Envelopes

Large buildings benefit from continuous EPS insulation on exterior walls, eliminating thermal bridges across steel and concrete structures. This application reduces HVAC loads and improves overall building performance.

Infrastructure Projects Like Roads and Utility Tunnels

EPS blocks are used in civil engineering for road embankments and underground utilities. Their strength and moisture resistance make them ideal for preventing frost heave and soil shifting.

Cost and ROI Analysis of EPS Insulation

Material Costs vs. Energy Savings

While EPS panels are affordable upfront, the long-term savings on heating and cooling costs make them even more attractive. A typical residential application pays for itself within a few years.

Lifecycle Cost Comparisons with Other Insulation Materials

Although XPS and Polyiso offer higher R-values per inch, their higher material cost and lower recyclability often make EPS the better choice over a building’s lifetime.

Long-Term ROI for Homeowners and Builders

Builders benefit from reduced callbacks and warranty claims when EPS is properly installed. Homeowners enjoy lower utility bills and improved comfort—benefits that add up significantly over decades.

Sustainability and Green Building Considerations

EPS and LEED Certification Credits

EPS can contribute to LEED points in areas like energy performance and material recyclability. Its long service life also reduces replacement waste.

Recyclability and Environmental Footprint

Unlike many foams that rely on chemical blowing agents, EPS production has a relatively lower environmental impact. End-of-life EPS can be recycled into new insulation or packaging materials.

Future Trends in Sustainable Insulation Materials

With increasing pressure for greener construction, EPS is expected to remain a major player due to its balance of affordability and performance. Innovations in recycling and composite systems will only strengthen its role.

Conclusion

Continuous and below grade insulation are non-negotiable for modern, energy-efficient construction. EPS delivers a rare combination of affordability, durability, and moisture resistance, making it an ideal solution for both DIY homeowners and large-scale contractors. By preventing thermal bridges, protecting foundations, and reducing long-term costs, EPS proves to be more than just insulation—it’s a foundation for sustainable building performance.

FAQ

1. Is EPS suitable for both residential and commercial below grade insulation?

Yes, EPS can be used effectively in both residential basements and large commercial foundations due to its strength and moisture resistance.

2. How does EPS handle water exposure compared to XPS?

While XPS resists moisture slightly better, EPS maintains consistent performance in damp soil environments when paired with proper drainage and vapor barriers.

3. Can EPS insulation be installed by DIY homeowners?

Yes. With basic tools and safety precautions, EPS is easy to cut and install, making it a popular choice for DIY basement or foundation projects.

4. What thickness of EPS is recommended for below grade applications?

Typical installations range from 2 to 4 inches, depending on climate zone and energy efficiency targets.

5. How long does EPS insulation last underground?

When properly installed with drainage and protection, EPS can last 50 years or more without losing significant thermal performance.